Embroidery

We have in-house embroidery design & production facilities.

With over 25 years experience in the embroidery industry we have the skills to tackle any kind of garment or decoration idea & are more than happy to advise you with the best solutions.

We have no minimum order & we treat all of your clients the same, whether they want one garment or many.

For any new design or amendment we will always email you a proof for approval before we commence embroidery onto your order.

We can embroider onto all types of garments, caps & hats, and produce embroidered or printed patches (in-house) to any shape, size or design.

Vinyl Printing

The CAD (Computer Aided Design)-Cut printing is a method of heat transferring onto T-shirts and clothing. It is most commonly used for printing the numbers, names, and logos onto sports T-shirts.

How does it work?

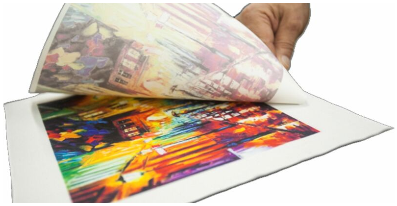

The process uses different types of vinyl which are cut, usually into a number or name, and then applied to the garment using a heat press. To ensure the cut is perfect, a computer is used to control the process. Then, the excess is picked out. This process is known as weeding. Once this has been done the material is heat-transferred onto the garment.

Types of CAD-Cut vinyl

Different vinyl colours and textures can be used to customise clothes further. The most popular one is plain block-colour but also available are effects in polka dots, chevrons, animal print, jeans, army, leather, and stripes. Before you choose a type, make sure you consider all the options. Maybe green zebra will work for a school team or club but not necessarily for a rugby team.

Pieces of vinyl can also be layered to create unique effects. The material usually comes in a roll and must be cut by an automated process. Choosing the right vinyl for the job means it will keep its pristine condition and won’t peel off after washes. The correct application is also vital.